State of the art technology aiding the analysis of your asset

Focusing on micro analysis to reveal major issues, metallographic and failure analysis methods can reveal the potential extent of corrosion by interrogating minute details.

Our metallographic and failure analysis methods make it easy to assess buildings, bridges, rails, tanks, tunnels, roads viaducts reinforced concrete, steel and composites.

Our expert team can help you:

Macrographic Examination

Our Canon DSLR with Macro Lens offers 1:1 high resolution and magnification up to 30x. With resolution of up to 200 µm allowing for detailed macrographic examination, articles such as cross-sections of pitted steel pipes, can be easily photographed and examined with this piece of equipment.

Combining the Canon DSLR with high quality glass graticules allows for the accurate cross section examination of coatings, corrosion, fractures which can be observed in concrete, metals, coatings, plastic, ceramic, composites and other construction materials. This can assist with identifying the location, type and cause of damage.

High Magnification Microscopy

Metallographic Microscopes are an inverted optical microscope, that offers 50 to 1000x magnification, allowing for detailed flat specimen and cross section examinations of materials such as metals, coatings, concrete and plastics.

High magnification can identify inherent defects in materials, including voids, cracks, inclusions and microstructures. This assists in analysing the initiation, propagation path, damage type and deterioration extent of materials present in various structures.

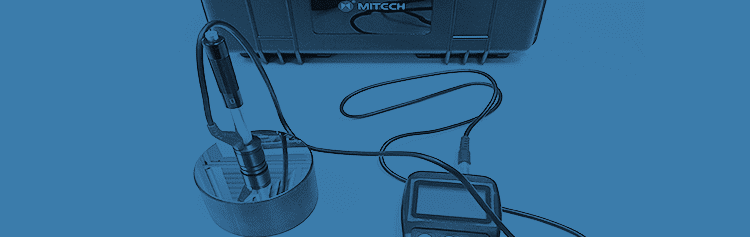

Leeb Rebound Hardness Tester

This piece of equipment allows for relatively non-destructive hardness testing and grade identification of metals used in steel structures. This allows for us to check the surface hardness of specific elements in buildings such as shafts, bearings, pipes and girders.

Rebound testing can be an effective way to confirm the grade of bulky, heavy, rigid metal samples and should be considered anytime ultrasonic thickness testing is performed. The hardness and approximate strength combined with dimensions can provide a good overall understanding of the structure or component.

This type of testing can also be used on other metals and alloys, however, it’s typically combined with chemical testing to ascertain more conclusive results.

Contact us to see how Infracorr can enhance the service life of your structure with cutting edge technology.